| Standard Test | Each valve is factory tested with nitrogen at 1000 psig (69 bar) for leakage at the seat and packing, the maximum allowable leak rate of 0.1 sccm. |

|---|---|

| Optional Hydrostatic test | This test is performed with de ionised water at 1.5 time the working pressure. Other tests like vibration, temperatures, helium etc are available upon requests. |

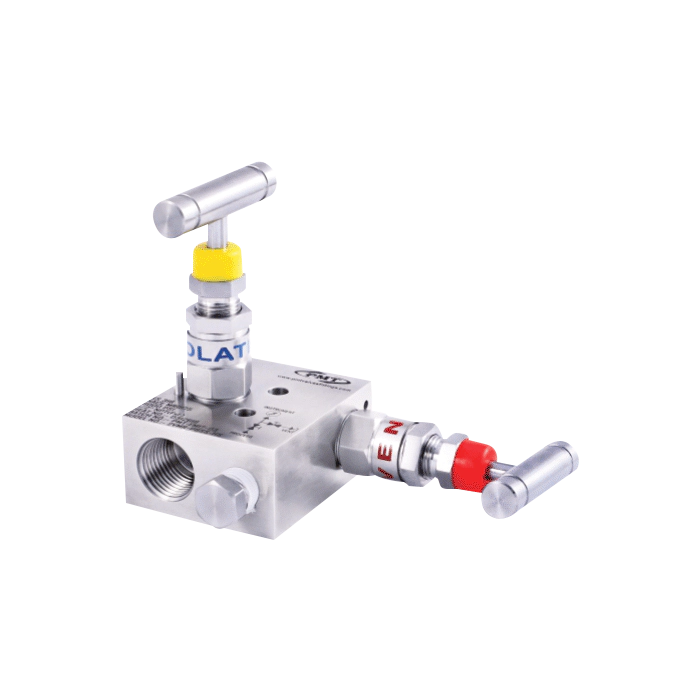

Valve manifolds are essential components used in hydraulic and pneumatic systems to consolidate multiple valve functions into a single, compact unit, streamlining the control and management of fluid flow. These manifolds combine several valves, such as directional control valves, pressure relief valves, or flow control valves, into a single assembly, simplifying system design and installation while reducing the number of connections and potential leak points. By integrating multiple valves, valve manifolds enhance operational efficiency, improve reliability, and facilitate easier maintenance and troubleshooting. They are widely used in various industries, including manufacturing, automotive, and aerospace, where they play a crucial role in controlling and directing fluid flow with precision and reliability.

We are involved in manufacturing and supplying a wide range of Straight Valve Manifolds , 2 Way Manifold Valve, 3 Way Manifold Valve and 5 Way Manifold Valve which are manufactured with quality material and latest process technology. Our products are in accordance with the requisite norms and standards to maintain the consistency in the prevailing market.

.jpg)